Inspection Time

Inspection Time

Tank Robotics

Pioneers in the development of Intrinsically-Safe (IS) In-Service Tank Robotics and Inspection Services

Our team of Above Ground Storage Tank managers have decades of out-of-service and in-service tank inspection experience. We have a depth of experience and knowledge in high density ultrasound scanning, equipment design, fabrication, and safe deployments. BSI and affiliates have inspected thousands of tanks worldwide while in service.

Kerosene/Diesel/Gasoline/Selected Chemicals/Water/Wastewater/Other

The Inspection Process

BSI’s in-service tank inspection intrinsically-safe (IS) scanners and non-IS scanners are designed to inspect the bottom of above-ground storage tanks without removing the tank from service, and without personnel entry into the tank.

- High density ultrasound scanners operate in both fixed and floating roof storage tanks.

- Deployed with the tank full of product

- A range of robotic equipment deployment options - from scanners that are maneuvered manually around the floor to multi-sensor remotely operated robots

- Video inspection where optically clear

- Precision navigation system

- API 653 certified inspectors

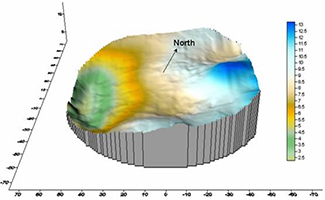

- 3D LIDAR laser scan tank analysis: settlement outer roundness, plumbness, berm capacity analysis, etc.

Reporting

- On-Site Preliminary Result Reporting

- Rapid Final Report Turnaround

- API 653 Compliant

When In-Service Makes Sense

- Where unknown conditions exist

- Integrity recertification

- A new tank where corrosion rate is not known

- Older tanks with known degradation

An in-service tank inspection provides the tank owners with the ability to plan for the optimum time for a full out-of-service inspection.

Deployed with the tank full of product, through an 18-inch or greater diameter inspection manways.

NO CONFINED SPACE ENTRY - Minimize/reduce environmental and personnel exposure

Corrosion rate and remaining tank floor life determination

Corrosion rate, tank contour, and remaining tank floor life determination

Benefits of In-Service Tank Inspection

Historically, when an above-ground storage tank requires a routine inspection, the tank must be taken out of service presenting an interruption in operations. Alternatively, an in-service tank inspection provides the tank owners with the ability to plan for the optimum time for a full out-of-service inspection, if necessary.

BSI offers high density ultrasound tank floor scanning with traditional compression wave ultrasound to collect floor thickness and settlement data at the same time. This provides a more realistic picture of tank settlement, a better analysis of tank floor integrity and a realistic calculation of the remaining useful floor life of the tank.

BSI’s In-Service tank inspection services provide skilled professionals, equipment and software responding to your unique needs and workflow requirements.